Top 5 Tips For Electric Motor Repair San Diego

The electric motor is a very vital component of most machines and problems with this component can even render machines and equipment useless. Therefore it is essential to keep your electric motors in optimal working condition through proper and regular maintenance. Electric motor repair San Diego ensures that your piece of machinery produces the proper amount of power for the particular job without any unnecessary strain. Here are some electric motor repair and maintenance concerns and tips for your equipment:

The susceptibility of electric motors to moisture is one of the main concerns. Condensation can easily cause the buildup of moisture in the interior parts of the motor especially when it is not being used and this can cause issues such as rust. Moisture can be controlled oiling up the bearing assemblies using grease that is infused with rust prevention substances. This is also an effective prevention measure of most moisture issues.

In most cases, start issues are caused by a faulty power supply. This can be solved by checking whether the power supply is working or whether the fuse has tripped. In case everything seems to be in order, the electric motor might need to be carefully cleaned. This can be done using an air compressor once the motor cools down.

Excessive noise that is coming directly from the electric motor might be sign of defect. The noise is usually caused by vibration problems which if not addressed immediately could cause further damage of the windings and bearings.

Bearing failure might eventually cause motor failure if not detected in time. This is because failing bearings can easily cause overheating or fail severely and do irreparable damage to the electric motor. One of the best ways of detecting bearing problems in time is by simply taking note of vibration trending of the motor. Excessive vibration is more often than not a result of problems with the mechanical system or a misaligned shaft. To prevent further damage, ensure that the electric motor is not subject to vibration caused by nearby motors that may be running and causing vibrations.

Electric motors usually heat up when they are under-ventilated. However, overheating is not a minor problem because it might even cause the system to malfunction. In order to overcome the problem of overheating, ensure that the fan is working and remove any debris and dirt that is preventing it from rotating properly. However, if motor’s fan is broken you might need to replace it.

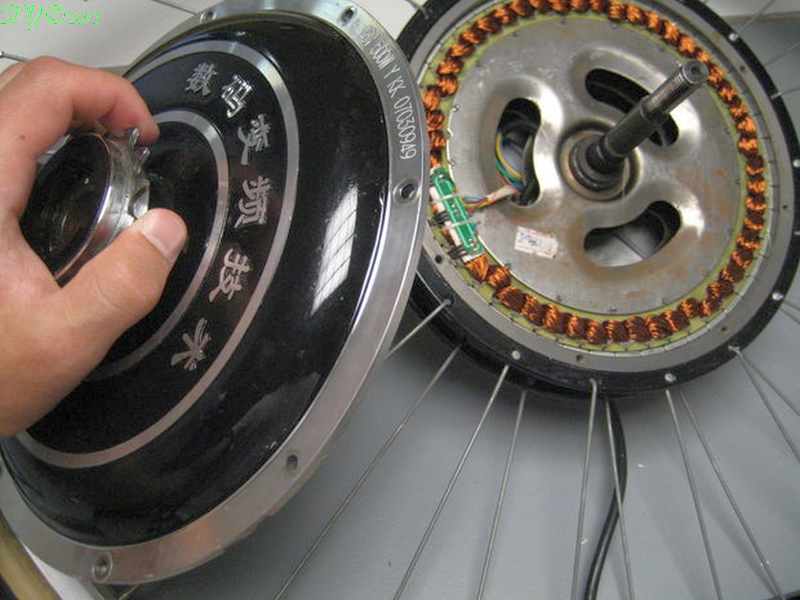

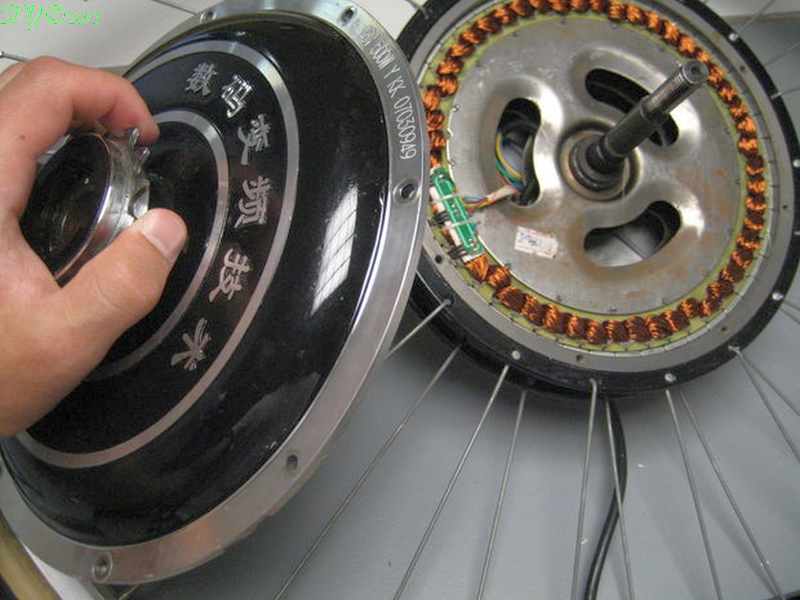

It is essential to understand the poor rewinds can cause decrease in the efficacy of eth electric motor. Therefore, it is essential to find a shop that offers extensive electric motor rewind repair in order to have a fast and reliable solution that does not reduce the reliability and efficacy of your motor. Companies who offer electric motor rewinds should have various assets and capabilities. They need to have experienced and qualified riggers who offer quality repairs. Therefore, it is essential to find electric motor repair company with services, guarantees and the necessary equipment to ensure that even after rewinds and repairs, your motors maintain their efficiency and reliability.

Sometimes it seems prudent to solve some problems yourself. However, it is essential to understand that this is not the ideal solution in all situations. You may end up losing a lot of your precious time which cannot be recovered or risk making the problem even worse.

Another factor that you should take into consideration is convenience. You can rest assured that with our electric motor repair San Diego services, your motor will be up and running in no time. Therefore, instead of working and waiting for several days to repair your motor you can simply let us repair it for you. Having your electric motor down for a long period might actually cost you more in down time than it costs to hire professional services.

At Propulsion Controls Engineering, we have the technical expertise and experience to detect and solve all mechanical problems. Besides, taking a shorter time, you can rest assured that our team will handle the job more efficiently. On the other hand, we can identify other non obvious issues that might cause problems later. Our team of certified professional gives their very best in each unique situation in order to meet your expectations and ensure client satisfaction.