New Technologies To Utilize In Safety Training Programs

With the rise of technology, industry professionals are consistently using new techniques for safety training programs and compliance standards. Previous to simulations, data mining, and augmented reality methods used in safety training, workers and managers were educated through information sessions and test-taking.

Although cognitive education through books and note-taking is important for general education and preparation, most workers learn on the job through application and simulation.

In order to empower workers on safety procedures and proper execution, repetition must be a major component of the educational process. Especially in the oil and gas industry, workers are subject to high temperatures and dangerous chemicals that can have terrifying repercussions for non-compliance. Within an industry like oil and gas, workers do not have the luxury of “starting over” and learning from mistakes because one mistake could cost a life.

Luckily, there are a few new technologies currently in use within safety programs that help train workers on the ground and controllers in the office through real-time situational training and development. Below are just of few of the main technologies currently gaining traction in the safety training business.

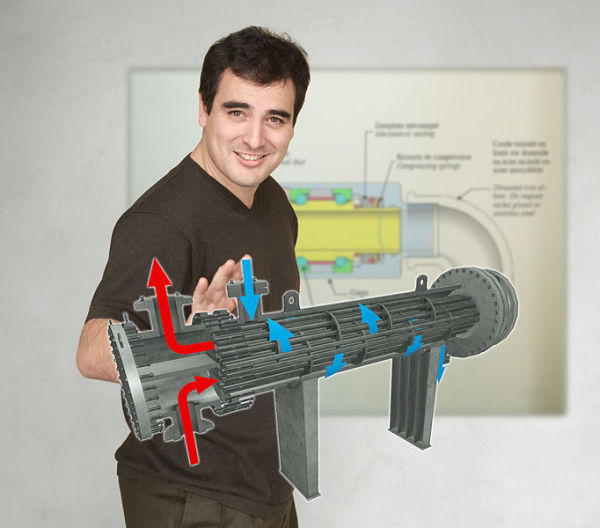

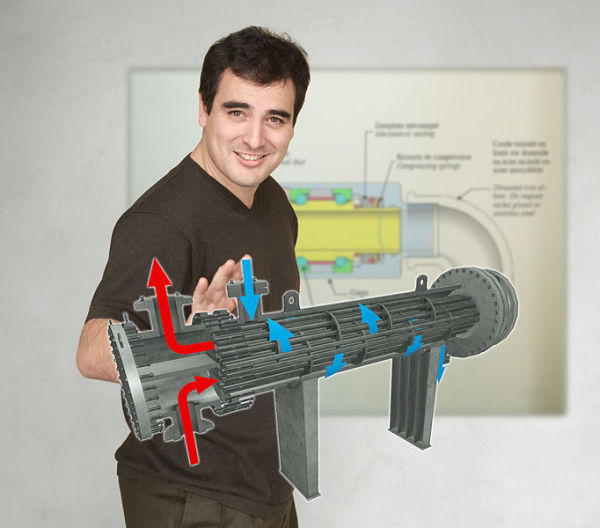

Top tech companies like Google, Microsoft, and HP are developing technology that goes beyond simulations. They are all working on augmented reality displays that help industries such as oil and gas, energy, aviation, and chemical. In fact, augmented reality is utilized to provide on-demand, on-site training for complex instruments used during oil exploration and drilling.

By integrating real world situations through digital mapping, AR anchors information when and where workers need it, rather than simulation techniques that are entirely computer-generated. AR superimposes computer-generated imagery over the worker’s view of the real world. This allows workers to synchronize their daily tasks quickly with the appropriate equipment and precautions for custom situations without interruption.

Simulation technologies prepare workers and safety managers for real-life scenarios. Industry professionals can learn complex procedures and processes quickly without eminent risk factors or dangers. Top simulation programs allow users to make mission-critical decisions under pressure in first-person position, similar to training previously used within the U.S. military training programs or NASA flight simulations.

For the oil and gas industry, training simulations are most effective for the operation of remotely operated vehicles, heavy equipment, and tubular handling – these simulation training exercises emphasize critical thinking, problem-solving, and skill application. OSHA and the EPA believe that on-site simulation training will improve immensely in the near future and will make the most of workers’ training hours while on the job.

In conjunction with augmented reality software, engineers and crew members on oil rigs will have access to real-time data. Using real-time data, it is possible to track processes, tasks, and monitor equipment. Particularly useful for initial the construction of oil rigs and drill installations, as well as oil refinery maintenance procedures, real-time data merges the physical and digital world for reconstructions and process management.

For example, Boeing is implementing virtual-reality glasses for workers assembling planes for commercial usage – the need for standardization and safe assembling is crucial for the industry and safety of passengers. Transferring this application to the oil and gas industry, engineers will be able to re-create oil drill assemblies for workers in the field doing maintenance or repairs to ensure proper installation without analyzing ex-post data such as product plans and blueprints.

In addition, the use of real-time data and AR-enhanced protective eyewear allows safe movement around low-light areas and obstructed viewpoints through re-creations similar to CGI techniques used in motion pictures. With real-time data on protective eyewear, workers will have access to updated safety procedures, will be able to log information about equipment hazards and life-cycles in real-time, and avoid potential accidents through customized job-site digital mapping.

http://www.rdmag.com/articles/2014/04/oil-and-gas-industry-training-requires-rich-new-technology

Matthew Hall is a freelance writer with a focus on health and safety and related topics. He talks about the latest technologies in the hopes of making life better for workers across all industries. For those needing to perfect their own health and safety programs he highly recommends turning to the experts at http://www.ecompliance.com.