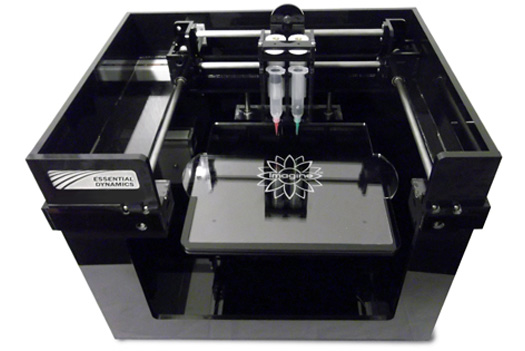

3D printing is the art of engineering a three-dimensional object. The tech itself has been around for two decades, mostly used in the commercial industry to develop prototypes. The software’s development has made it accessible to greater numbers. Today, there are companies like Scuplteo and Ponoko. They’re bringing 3D production to the marketplace, offering to build 3D models from furniture to custom t-shirts. Blueprinter is working on an inexpensive 3D printer.

Soon, consumers will use their creativity to construct products of their own design without needing strong 3D or graphic skills. This technology will save hours, days, on shopping for the perfect dress or couch. One would simply get on the computer, design and print with 3D tools.

The Tech

The Tech

To print in 3D, you need the basics: a 3D application and a 3D printer. While most 3D printers can handle a number of materials, most can only print in plastic and metal. There is software, such as 3D Max, that creates 3D models, but the critical component is the 3D printer. The 3D printer will take the model, and using layer on top of layer of material, will print out an actual model. The detail and size will be dependent on the power of the printer.

Getting Started

Though there are expensive professional level applications, we’ll use Tinkercad. It’s a free app that will run inside a browser. Its level of functionality is perfect for a beginner, while still powerful enough to design real 3D models. Like a solid CAD program, it models agglomeration of points in space as opposed to hollowed, stitched polygons. This makes Tinkercad suited for 3D printing.

After creating an account at tinkercad.com, open a blank slate, or open work plane. In ADD mode, select a shape along with a size. You can click and drag on the shape.

An easy project to start is a shirt button. Use the ADD tool to place, or stamp, a disc. Use the SUB tool to set it at 4 mm wide and 3 mm thick. Stamp two buttonholes at the center of the object. Viola! A button.

Of course that only took a few minutes. A model can take hours, or months, depending on its complexity. There’s shaping, trimming, cutting, accenting, subtracting and more. There’s the attention to the smallest detail because your 3D print out — the final model —is only going to be as good as the design.

3D Printing

3D printers are relatively expensive, used by industrial and commercial properties. Companies like Scuplteo use these high end units. For our purposes, we’ll utilize shapeways.com, an online 3D printing service. Depending on the budget, they can print your 3D model in ceramic for as little as $25 or up to $900 for a sterling silver cast, with many material options in between.

Export your 3D model to an appropriate file. .STL is the industry standard. Upload it to shapeways. They will let you know when it’s approved. From that point, they will print and ship it to you.

Summary

It’s a promising future for consumer freedom. No longer search for the perfect purse, shoe or couch. No longer shop for the perfect gift. Take t-shirt printing to an entirely new plateau. Create it yourself and have it 3D printed.

3D graphics are very popular in all spheres of life, in the videos and graphics, and more recently in T-shirt printing with 3D applications. 3D graphics have given special form of technology and fashion.