Tantalum Polymer Capacitors

In the modern passive components industry, there has been a huge demand for reliable components with small form factors. Tantalum capacitors are considered as the best choice for applications that require high capacitance values along with small components. They are electrolytic capacitors that form an important part of electronic circuits. Their origin dates back to 1950 and today they are still widely used due to their capacitance range, voltage range, impedance characteristics, reliability and physical size.

Tantalum capacitors are constructed such that the anode is made in form of a pellet of tantalum metal. An insulating oxide layer acts as the dielectric and covers the anode. The dielectric in turn is covered by a cathode made of a conductive material. Initially, tantalum polymer capacitors used a manganese dioxide cathode. This approach proved to be a highly reliable solution along with high volumetric efficiency for over 50 years. However, it has some drawbacks. The high oxidation present in MnO2 offers ignition risk. Moreover, MnO2 being a semi-conductive material causes an increase in total ESR (Equivalent Series Resistance) of the component. One of the most important characteristic of ideal capacitors is that they should offer low ESR.

The following three features forms the research ground for development in the technology of tantalum capacitors:

In 1990s a major innovation was made by replacing the semi-conductive solid state cathode material with a highly conductive polymer cathode system. This polymer cathode not only provides 100 times more conductivity than MnO2 but also eliminates the risk of ignition due to the absence of oxygen. Due to improved functionality, tantalum polymer capacitors became widely popular in the design community as engineers begin to use them on power supply’s output rails in place of MnO2 tantalum capacitors and Multilayer Ceramic Chip (MLCC) capacitors. Polypyrrole, Polyaniline, and Polyethyldioxythiophene (PEDT) are some of the conductive polymers that can serve as the cathode material in tantalum polymer capacitors.

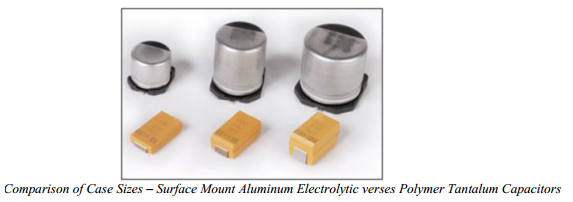

Tantalum polymer capacitors offer various advantages and are continuously being improved to develop higher CV (capacitance times voltage constant) powers. The advancements have led to the creation of high capacitance capacitors with smaller case size dimensions.

The case heights of polymer tantalum capacitors, that are currently available, range from 2.0mm to 4.3mm. This is the most ideal case size option providing high CV values as compared to any other capacitor technology.

The second electrode in a capacitor is very important as it acts as a vital factor for ESR. The introduction of polymer electrode has led to significant reduction in ESR. The polymer technology decreases the ESR value by about a quarter compared to the MnO2 electrode. At frequencies greater than 100 KHz, this reduction is very prominent. This feature considerably improves the filtering performance of tantalum polymer capacitors in DC-DC converters and other applications that require this frequency range. They are said to retain more than 90% of their capacitance value at 100 KHz.

The absence of oxygen in the structure reduces the ignition of these capacitors. Conductive polymer has its own self-healing reaction which is significantly less effective than that of MnO2.

Voltage derating, a requirement of certain applications, is improved due to deployment of polymer electrode. In conventional MnO2 tantalum capacitors, during the board mounting process, damage is induced on the dielectric due to mismatch in the coefficient of thermal expansion and material sets. The rigidity of MnO2 fails to provide protection from the expansion and contraction of the other materials around the anode. This problem is resolved in case of polymer electrode due to low temperature processing, softness and flexibility. There is an improvement in the dielectric condition after the board mounting allowing increase in applied voltages without compromising on reliability. A tantalum polymer capacitor maintaining 20% derating offers same amount of reliability as that of a MNO2 tantalum capacitor with 50% derating.

Despite of all these advantages tantalum polymer capacitors also offered some limitations. Undoubtedly, the advent of polymer technology exhibited multiple improvements but the downside was that the manufacturers were unable to introduce a reliable design for applications requiring output voltages greater than 20V. Until 2003, the maximum rating provided by these capacitors was 25V and that also with compromised reliability. This led to the need for provision of higher voltage ratings and long term reliability at higher voltages.

In 2008, industry leaders made a remarkable advancement by developing polymer tantalum chip capacitors with a rating of 35V. This breakthrough was made by using new polymer materials and process techniques that provide a strong dielectric capable of withstanding voltage stresses of around 28V. The breakdown voltage (VBD) which determines the ability of the capacitor to withstand high voltage should be higher for better reliability. For these high voltage rated capacitors is greater than 60V.

Tantalum polymer capacitors are sensitive to high temperatures. The reason is that conductive polymers are thermally less stable due to weak bond strength. Bonds in organic polymers start breaking down at 200°C.Due to this fact, maximum temperature range offered by the manufacturers of tantalum polymer capacitors is 105°C. This maximum allowable value has been upgraded to 125°C by some manufactures. The capacitor element is carefully sealed within the protective epoxy case to withstand this temperature range.